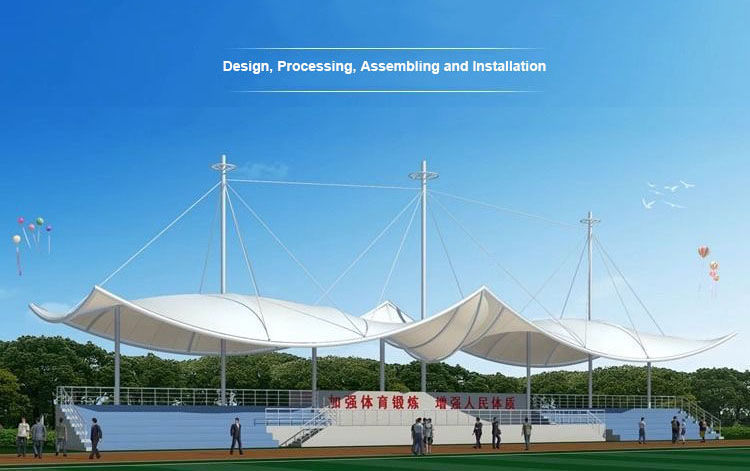

Membrane Structure Shade for Scenic Regions

A membrane structure shade in scenic regions refers to a lightweight, architecturally striking canopy made from tensioned fabric membranes (PTFE, PVC, or ETFE) supported by steel frames or cables. These structures blend durability with artistic design, providing shade, weather protection, and visual enhancement for parks, resorts, plazas, and tourist attractions.

Why Use Membrane Shades in Scenic Areas? The Membrane Shades Are Popular in Scenic Regions for The Following Features:

1. Stunning Aesthetics

Sleek, curved designs complement natural landscapes.

Custom shapes & colors (translucent/opaque) for thematic integration.

Lightweight & airy, avoiding visual obstruction of scenic views.

2. Superior Weather Protection

UV-resistant (blocks 90–99% of harmful rays).

Waterproof & windproof (pre-tensioned fabric withstands storms).

Heat reduction via reflective/ventilated designs.

3. Open & Spacious Coverage

Column-free spans (up to 50m+) for unobstructed gathering spaces.

The are Ideal for:

✓ Park pavilions

✓ Resort pool shades

✓ Observation deck covers

✓ Picnic zones & walkways

4. Eco-Friendly & Low-Maintenance

Self-cleaning coatings (e.g., PTFE) reduce dirt buildup.

Minimal foundation impact (preserves natural terrain).

Long lifespan (20–30 years with PTFE).

Common Applications in Scenic Spots

| Location | Purpose | Example |

|---|---|---|

| National Parks | Rest areas, trailhead covers | Yellowstone shaded seating |

| Beach Resorts | Poolside cabanas, lounge shades | Maldives resort canopies |

| Botanical Gardens | Greenhouse extensions, walkway roofs | Singapore Gardens by the Bay |

| Plazas & Squares | Event spaces, outdoor cafes | Dubai Miracle Garden |

What Are The Material Options for Scenic Shades

PTFE-Coated Fiberglass

Best for permanence (30+ years lifespan).

Milky-white, diffuses light beautifully.

PVC-Polyester

Cost-effective, vibrant colors (10–15 years lifespan).

ETFE Foil Cushions

Ultra-lightweight, transparent (modern "bubble" look).

Key Advantages Over Traditional Roofs

✔ Faster installation (prefabricated modules).

✔ Energy-efficient (reduces cooling loads).

✔ Adaptable to complex terrains (hillsides, water edges).

Ideal for Tourism & Eco-Projects

Enhances visitor comfort without harming nature.

Iconic landmarks (e.g., Denver Airport Roof, Cable Beach Shades).

Need a custom design for your scenic area? Let’s create a shade that blends art + function!

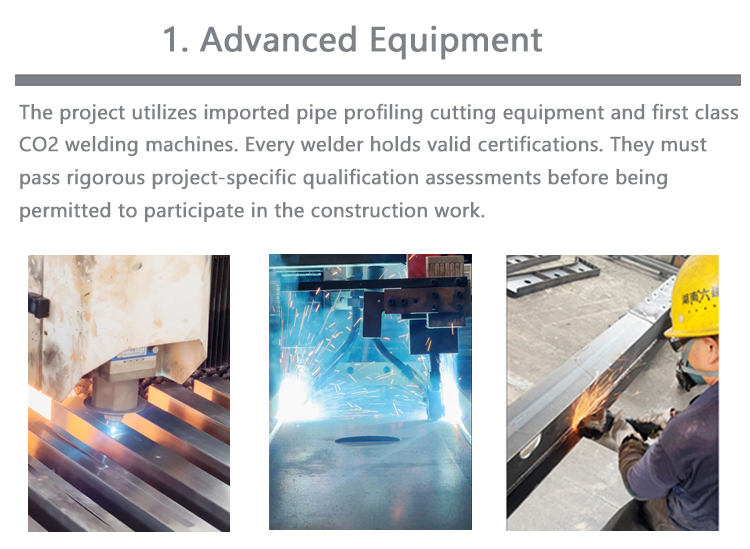

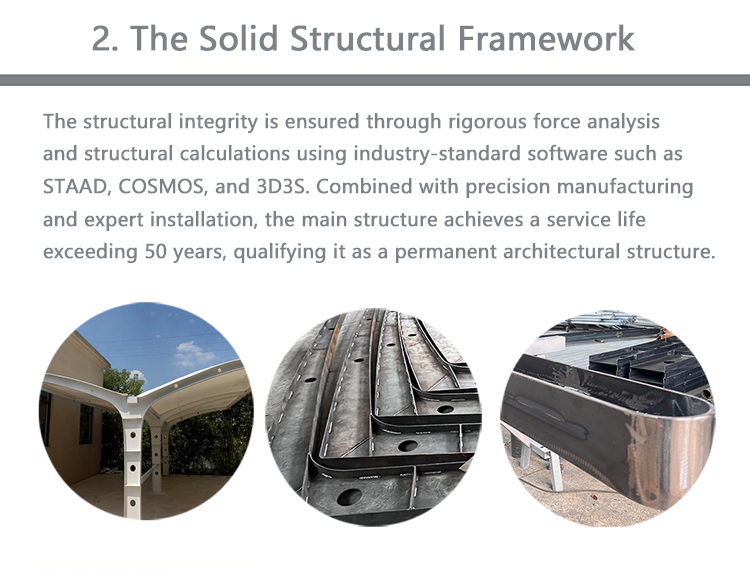

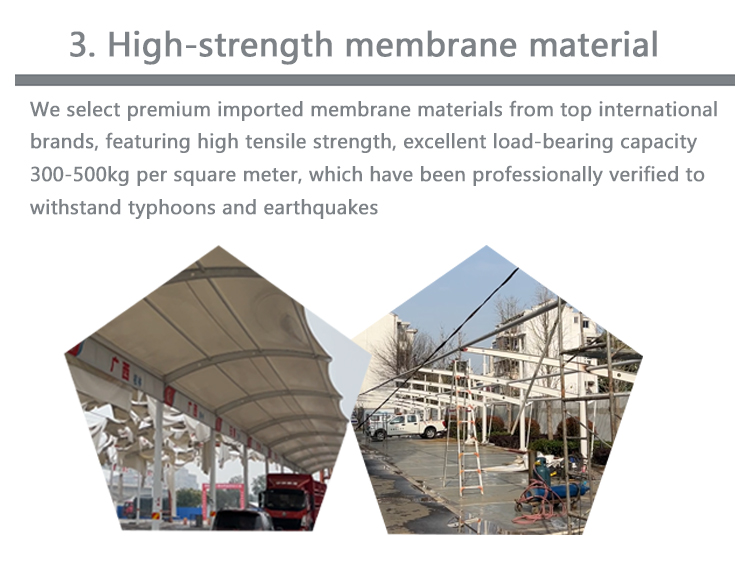

The Reasons for Choosing us

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: kelly Wong

Phone: +86-19911319693

E-mail: support@aolii.com

Add: Office Address: Building 10, Hejiaping Creative Industrial Park, Wuling District, Changde City, Hunan Province, SASTON

Factory Address: Building 003, Industrial Park, Wuxi Town, Luxi County, Tujia and MiaoAutonomous Prefecture,Xiangxi. Hunan Province